[ad_1]

GROB is a pioneer of electromobility: The manufacturing expertise and course of experience of the Bavarian family-owned firm are utilized by greater than two-thirds of all suppliers of EVs. GROB has earned this market management not solely via braveness and foresight, but in addition via top quality requirements. With its complete portfolio of high quality options, ZEISS helps to all the time obtain these requirements and noticeably improve productiveness.

Electrification is a key financial and ecological success issue – particularly within the mobility sector. It’s usually mentioned that Germany has been left behind internationally with regards to electromobility. However at GROB, a provider of producing and automation programs, they solely smile at such statements. Martin Negele is head of high quality assurance on the long-established Mindelheim-based firm. He says: “At GROB, we acknowledged a number of years in the past that the long run belongs to e-drives.”

“At the moment, this was nonetheless a controversial subject, however we took the plunge.” This has paid off: “In the present day, we have now a 67 % market share in stator expertise alone. In the event you take a look at an e-drive prepare, it is rather seemingly that our manufacturing expertise is behind it,” Martin Negele explains. GROB earns this main function primarily by striving for uncompromising high quality. To make sure this, the corporate depends on an in depth partnership with ZEISS.

With its Industrial High quality Options division, ZEISS is the one supplier to supply a whole portfolio of state-of-the-art high quality options: “We mix microscopic, tactile and optical measurement expertise to attain optimum outcomes”, says Martin Negele. Which means even the manufacturing of a demanding half akin to a stator will be absolutely coated – with most certainty and productiveness.

Stator: Challenges in manufacturing and high quality assurance

Along with many different benefits, the drive expertise of EVs impresses with its basically easy design: In an electrical motor, a rotating electromagnet, the rotor, turns within the magnetic discipline of an immovable everlasting magnet, the stator. Nonetheless, the manufacturing of those parts, particularly the stator, is something however easy – even when, roughly talking, it solely consists of a sheet steel housing, the laminated core, and induction coils product of coated copper. Even with such a “easy” element, nevertheless, there are excessive efficiency necessities in the present day. Because of this, automotive producers are additionally more and more utilizing hairpin expertise, i.e. plug-in coils, as an alternative of winding wire coils for his or her stators.

Hairpin coils have main benefits, together with increased motor efficiency mixed with decrease weight. And hairpins will be mass-produced extra simply and effectively – an necessary facet in view of the rising demand for EVs.

“As advantageous as hairpins are as a completed product, their manufacture is demanding, particularly with regards to bending and welding”, explains Georg Knoll. In the present day, the skilled welding engineer oversees the welding processes at GROB and manages the workshop testing laboratory. “That’s why we have now to always verify from incoming items to the completed assembled half: How is the bending habits of the wire, does the geometry match, does the insulation layer of paper sit between the hairpins and the sheet steel package deal, do the welds match?” As a result of undetected defects can result in lack of efficiency or inoperability, and within the worst case even to deadly injury to all the drive.

High quality options for the whole manufacturing course of

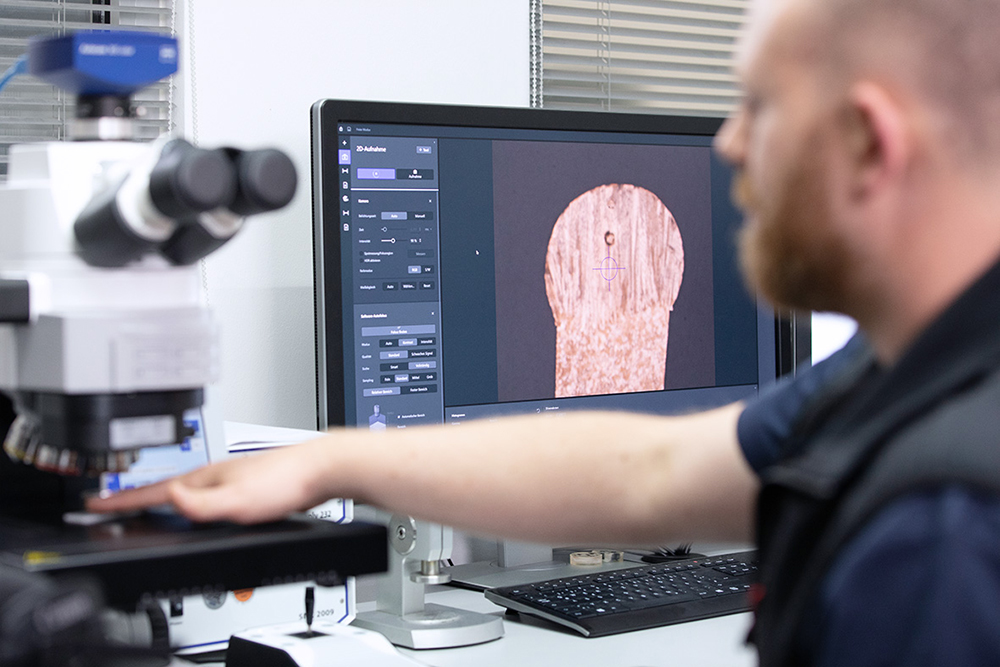

“Our declare is that we ship a high manufacturing course of to our prospects, and our high precedence is uncompromising high quality,” says Martin Negele. “That’s why we additionally take note of high quality assurance options within the manufacturing course of, which meaningfully safeguard each single step. On this approach, we all the time present our prospects with the understanding of persistently top quality.” A decisive focus is on the copper wire from which the hairpins are bent. On receipt of the products, a tensile take a look at is first carried out, then a cross-section of the wire is analyzed below the microscope with the help of a metallographically floor pattern. The visible inspection offers details about homogeneity and abnormalities on the floor, particularly concerning the situation of the insulation coatings – features such because the thickness and measurement of the coating layer, dimensional accuracy, and deviations from the CAD mannequin.

“It’s important for the manufacturing course of that we see how the coiled wire behaves once we uncoil it for additional processing, but in addition when it comes to reverse bending habits,” says Martin Negele. “Solely with this information can we assure persistently good outcomes.” Within the subsequent step, the wire is bent into hairpins and the result’s checked tactilely and optically on a multi-sensor coordinate measuring machine to make sure dimensional accuracy and homogeneity even when prepared for meeting. As soon as the hairpins have been joined within the stack of sheets, additional inspection steps comply with: The welded ends of the hairpins are inspected with a pc tomograph. “As an skilled welding engineer, that is after all significantly necessary to me that we do a clear job right here,” says Georg Knoll. “We’ve to have the ability to detect pores above a sure measurement or quantity in order that we will regulate our processes accordingly.”

Normal from ZEISS used results in 30 % increased productiveness

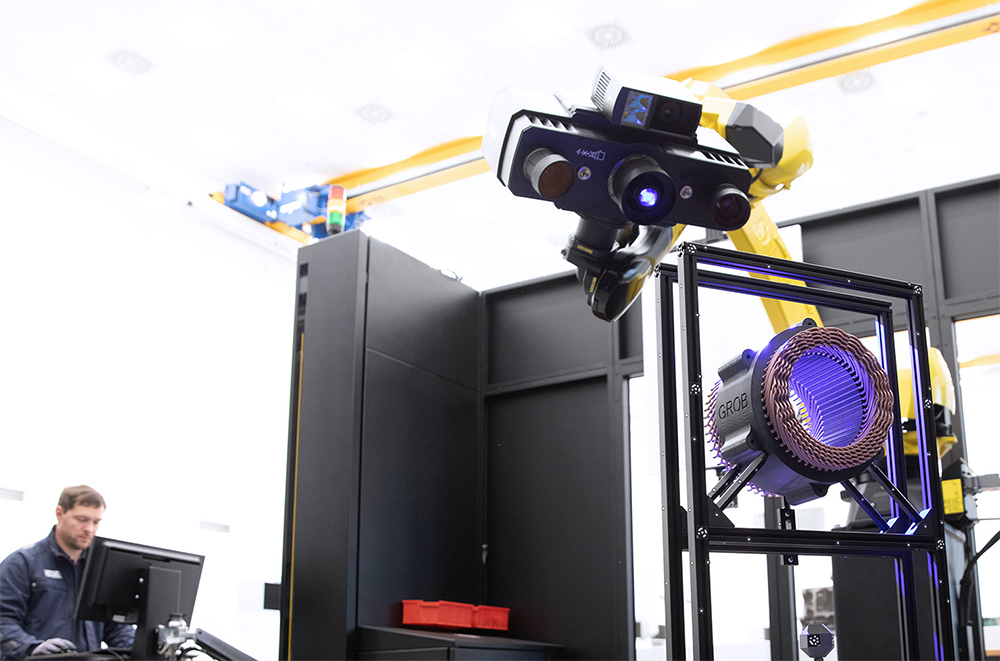

A look into the measuring room – a corridor of spectacular measurement – reveals a transparent model desire in high quality assurance expertise: one ZEISS machine stands subsequent to the opposite. As coordinate measuring machines, GROB depends on ZEISS PRISMO – one of the exact of its sort. ZEISS ScanBox features as an automatic optical 3D measuring machine – it concurrently permits excessive course of reliability and a excessive throughput. And GROB additionally depends on confirmed ZEISS expertise for microscopy with the ZEISS Axio Imager, an open microscope system for automated supplies analysis. “With solely few exceptions, we persistently depend on options from ZEISS,” explains Martin Negele.

“And there are a number of causes for this: First, hardly another provider provides its industrial prospects such a excessive degree of service and utility understanding. That merely convinces us again and again within the buying section. And: No different provider provides such a complete portfolio with which we will cowl a whole course of such because the manufacturing of a stator.” The truth that nearly all of the units within the measuring room come from ZEISS will not be an finish in itself, however has tangible benefits, emphasizes Martin Negele: “The uniform ecosystem saves us coaching effort and makes it simpler for our workers to function the completely different options. And it makes workload planning extra versatile and environment friendly.”

Because of this, our productiveness has elevated by 30 %.

Georg Knoll provides: “And when our prospects see our high-quality gear from ZEISS, there are not any discussions in any respect about high quality claims or measurement values. They know that we make use of cutting-edge options; in any case, most of them have ZEISS gear themselves.”

Know-how leaders work collectively on the way forward for e-mobility expertise

Because of the long-standing partnership, a relationship of belief has been established between GROB and ZEISS that goes past a mere supplier-customer relationship. GROB can be a pilot buyer for brand new high quality applied sciences from ZEISS earlier than they’re formally launched in the marketplace, and helps their growth with suggestions. “This provides us entry not solely to the present cutting-edge in high quality assurance options, but in addition helps form them,” says Martin Negele.

“This matches in with our declare that we need to keep one step forward of our prospects, who’re already working at an awfully excessive degree, with regards to high quality. That is significantly necessary with new and rising applied sciences akin to e-motors or batteries – there’s a lot to be gained for the pioneers, however provided that they ship high quality. With ZEISS as our associate, we have now the understanding of all the time having the ability to sustain with the leaders.”

ZEISS Industrial High quality Options

information.metrology.us@zeiss.com

1-800-327-9735 zeiss.com/metrology

[ad_2]