[ad_1]

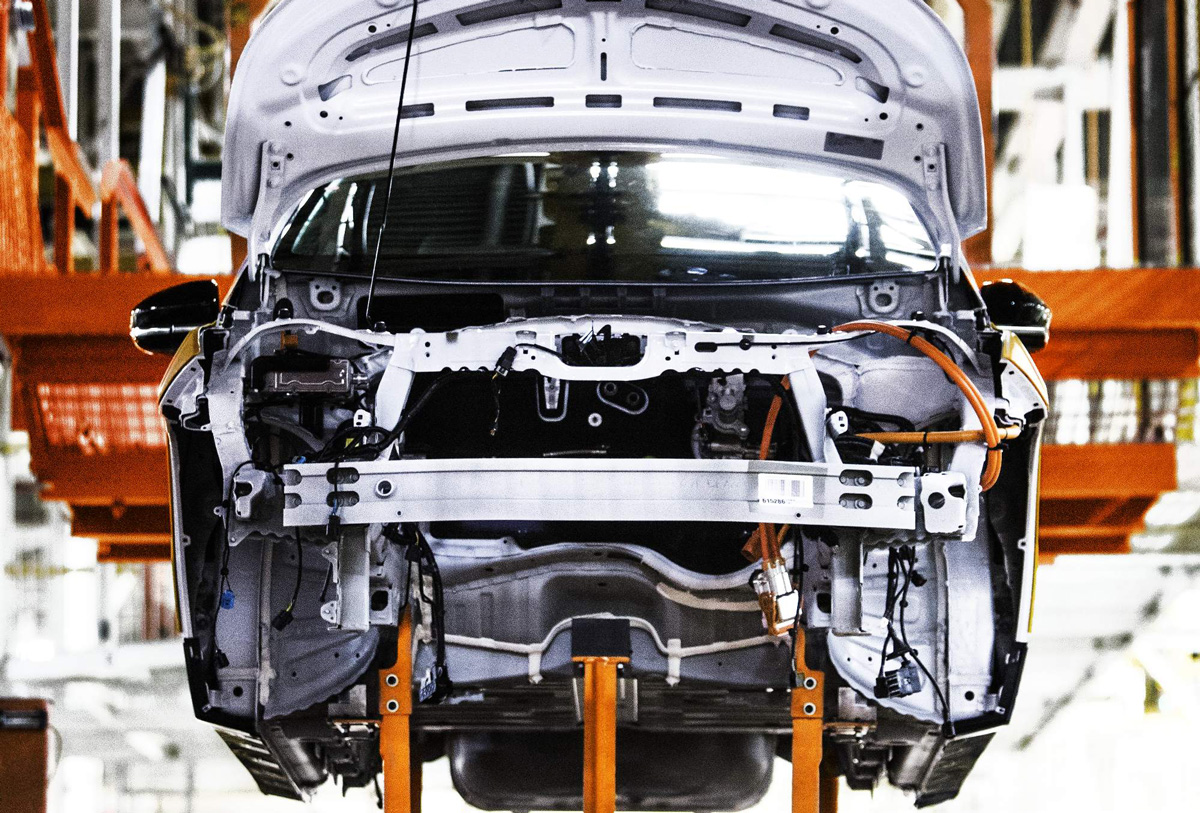

Tesla’s gigacasting course of, which makes use of big casting machines to make automobile our bodies with only a few huge forged components, permits the corporate to tremendously simplify chassis assemblies, saving a great deal of time, cash and manufacturing facility area. Different automakers, together with Ford, Hyundai and several other Chinese language manufacturers, have taken a eager curiosity within the know-how.

Tesla’s course of depends on huge Giga Presses from Italian agency Idra, which have been the topic of many a gee-whiz YouTube video. An organization referred to as Tooling & Tools Worldwide (TEI), a specialist in sand casting methods, is way much less well-known, however has additionally performed a key function in Tesla’s improvement of gigacasting molds.

Now it seems that GM, for as soon as, could have stolen a march on Tesla by buying TEI, which grew to become a part of GM’s International Manufacturing division in July. “Sources with direct data” informed Reuters that GM paid lower than $100 million for TEI. It’s unknown whether or not Tesla was additionally amongst bidders for the corporate.

“TEI will stay its personal enterprise entity with GM as its dad or mum firm,” GM mentioned, including that it acquired TEI “to bolster its portfolio of improvements and safe entry to distinctive casting know-how.”

It additionally scored a uncommon PR victory over the smug California (oops, make that Texas) carmaker. The unnamed sources informed Reuters that the TEI acquisition is a part of GM’s technique to catch as much as Tesla. We have been starting to doubt that the automaker had any such technique, after its current shot in its personal company foot.

Tesla could need to scramble to discover a substitute for TEI, or—because it has usually accomplished prior to now—develop the mandatory experience in-house. Reuters has reported that Tesla relied on TEI and three different suppliers, for a fast prototyping method that makes use of casts made out of business sand.

Ranging from a digital design, TEI and its colleagues use 3D printers referred to as binder jets to construct sand molds that may forged molten alloys. These could be printed shortly and cheaply, permitting Tesla to swiftly iterate designs for physique components.

Based on Reuters, TEI started working with Tesla in 2017 to develop Mannequin Y, and has since been concerned in gigacasting mould prototyping for Tesla’s Mannequin 3, Cybertruck and Semi.

GM additionally has historical past with TEI. In 2021, the 2 corporations labored collectively to create underbody castings for the upcoming Cadillac Celestiq EV, and TEI invested in a brand new devoted manufacturing line for the Celestiq. This led to TEI successful the casting trade’s equal of an Oscar: the 2023 Casting of the Yr award from the American Foundry Society.

Supply: Reuters

[ad_2]