[ad_1]

Sponsored by Indium Company

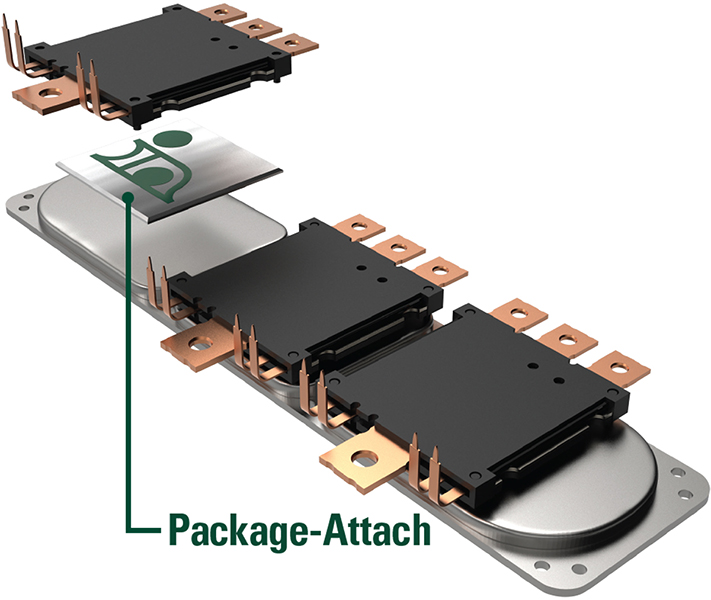

Within the ever-evolving panorama of electronics manufacturing, innovation is the important thing to staying forward. Indium Company®, a number one participant within the business, has as soon as once more demonstrated its dedication to development with the introduction of Indalloy®301 LT. This novel alloy know-how is particularly designed for energy module package-attach purposes and allows decrease processing temperatures in preform soldering.

Quest for Decrease Processing Temperatures

One of the crucial thrilling options of Indalloy®301 LT is its capability to facilitate decrease processing temperatures. It is a game-changer, particularly in energy module purposes, the place thermal administration is essential. Bundle-attach soldering is a strong and dependable thermal administration methodology, nevertheless the required processing temperatures for present state-of-the-art Pb-free alloys could cause catastrophic unwanted effects similar to mildew delamination within the energy module. By lowering processing temperatures, Indalloy®301 LT addresses this widespread problem confronted by producers—how one can obtain sturdy solder joints with out subjecting the module package deal to extreme warmth. The flexibility to scale back processing temperatures, and thereby vitality consumption, can also be of accelerating significance as producers try to scale back their carbon footprints.

Assembly the Calls for of Mission Profiles

The calls for on energy electronics purposes, particularly in areas like electrical automobile (EV) energy module-cooler integration, are frequently growing. Indalloy®301 LT rises to the problem by providing superior thermal and mechanical efficiency in comparison with conventional thermal interface supplies. When leveraged with this new alloy know-how, preform soldering can stop points like warpage, encapsulation breakdown, and delamination by lowering processing temperature.

Bismuth-Free Benefit

What units Indalloy®301 LT aside is its bismuth-free composition. Conventional low-temperature alloys usually comprise bismuth which, whereas efficient in decreasing melting factors, comes with its personal set of challenges. Bismuth-containing alloys are identified to compromise reliability over time, resulting in thermal defects in modules. Indalloy®301 LT eliminates this challenge, providing a dependable various that doesn’t sacrifice efficiency.

Configurations for Each Want

Indium Company understands the varied necessities of the electronics business. To cater to completely different preferences and purposes, Indalloy®301 LT is accessible in varied configurations, together with InFORMS®, preforms, and ribbon. This versatility permits producers to decide on the format that most accurately fits their manufacturing processes, guaranteeing seamless integration into current workflows.

InFORMS® for Consistency and Power

InFORMS® configurations of Indalloy®301 LT deliver a brand new degree of consistency to soldering processes. Constant bondline thickness and improved energy improve each thermal and mechanical reliability of solder joints. That is significantly vital in energy module purposes, the place the efficiency of solder joints can instantly impression the effectivity and longevity of digital units.

Enabling Pb-Free Excessive-Reliability Alloy Applied sciences

Indalloy®301 LT doesn’t simply cease at addressing thermal defects. Its decrease processing temperatures open the door for complementary Pb-free high-reliability alloy applied sciences, similar to Indalloy®276. This permits prospects to make the most of superior alloys in energy module die-attach, component-attach, or interconnects with out the danger of re-melt and degraded efficiency.

Key Options of Indalloy®301 LT

- Diminished Peak Reflow Temperatures: By lowering peak reflow temperatures 50°C in comparison with generally used alloys in energy electronics meeting, Indalloy®301 LT minimizes stress on the ability module package deal.

- Prevention of Warpage and Delamination: Indalloy®301 LT prevents warpage and eliminates delamination in molded energy module package-attach purposes.

- Glorious Thermal and Electrical Conductivity: The alloy maintains glorious thermal and electrical conductivity, guaranteeing optimum efficiency in various digital purposes.

- Stable Reliability Efficiency: Indalloy®301 LT with its bismuth-free composition displays strong reliability efficiency inside a large temperature vary (-40°C–125°C), assembly the stringent necessities of assorted mission profiles.

- Means to Step-Solder with Pb-Free Alloys: The flexibleness of Indalloy®301 LT permits for step soldering with Pb-free alloys, increasing the vary of purposes and design potentialities.

- Diminished Vitality Consumption: Decrease processing temperatures not solely profit the integrity of digital elements but in addition contribute to decreased vitality consumption throughout manufacturing, aligning with sustainability targets.

- Obtainable in Numerous Configurations: Whether or not in preforms, ribbon, or InFORMS®, Indalloy®301 LT supplies flexibility and comfort for various manufacturing setups.

Conclusion

Indium Company’s new Indalloy®301 LT is a exceptional addition to the world of soldering applied sciences. Its bismuth-free composition, decrease processing temperatures, and various configurations make it a flexible answer for energy module package-attach purposes. By addressing thermal defects with out compromising reliability, Indalloy®301 LT opens up new potentialities for designers and producers within the pursuit of enhanced thermal and mechanical efficiency in digital units. Because the business continues to evolve, improvements like Indalloy®301 LT are set to play a pivotal function in shaping the way forward for electronics manufacturing.

For extra details about Indium Company’s high-reliability alloy merchandise, go to www.indium.com/merchandise/solders/solder-alloys/ or contact Joe Hertline at jhertline@indium.com.

[ad_2]