[ad_1]

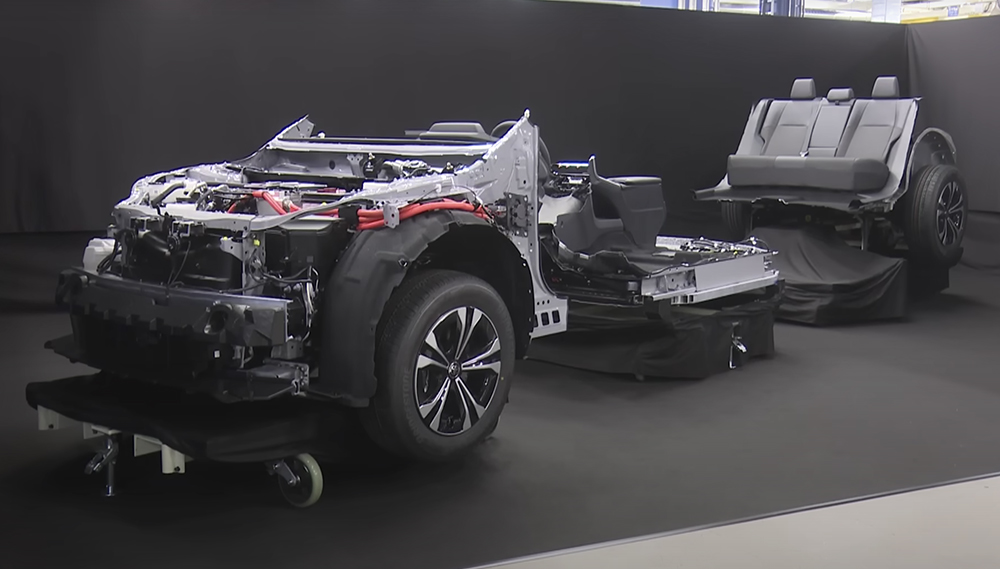

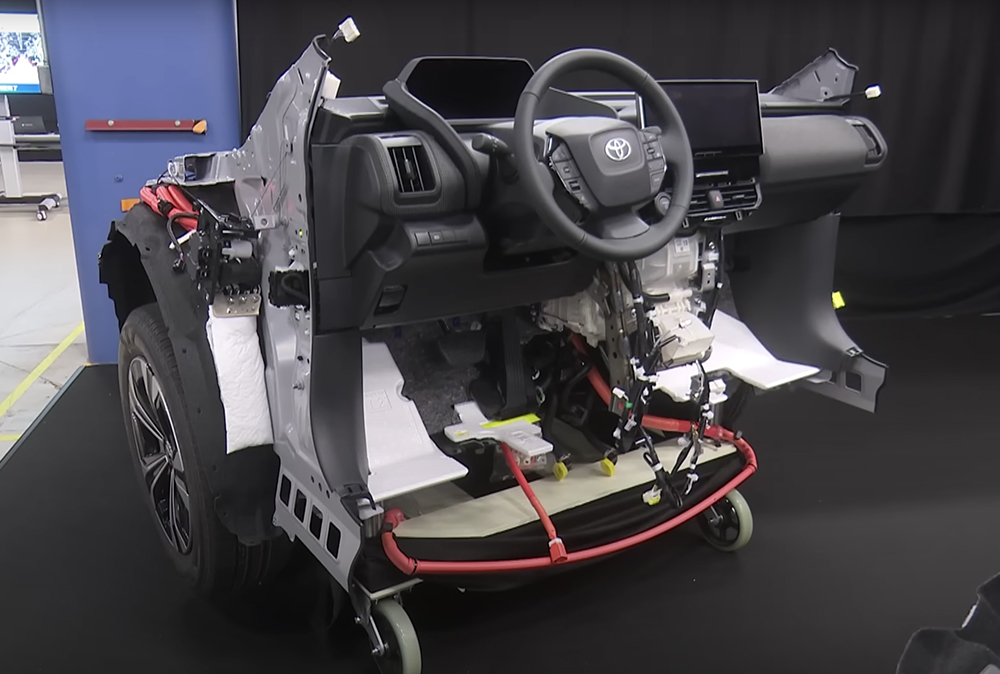

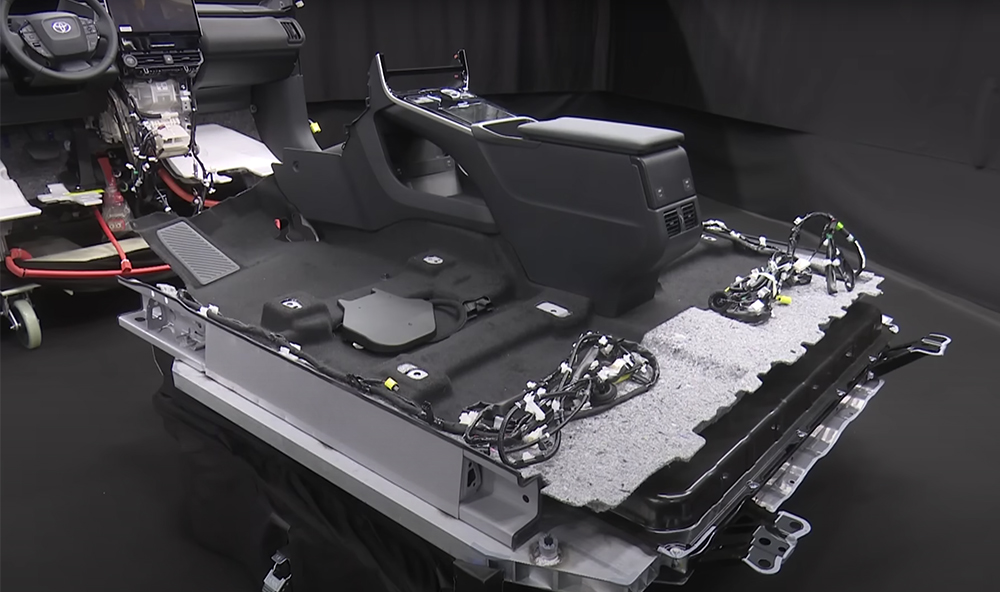

It’s been a very long time since auto business observers have seen Toyota as an innovator, so it was a nice shock when the world’s second-largest automaker demonstrated a model of the die-casting course of pioneered by Tesla, utilizing an enormous hydraulic press to solid all the rear third of an auto chassis as a single piece.

As reported by Nikkei Asia, this chassis part may exchange an meeting that’s at the moment made up of 86 particular person elements in a 33-step course of. Amongst different advantages, this might cut back manufacturing time for the half from a number of hours to 3 minutes.

Toyota hopes the die-casting course of (or gigacasting, to make use of the time period coined by Tesla), mixed with different manufacturing advances, will cut back whole meeting occasions by 50%. The carmaker plans to point out off a few of its new processes and applied sciences in an idea EV at subsequent month’s Japan Mobility Present, and says it would use gigacasting to make the entrance and rear sections of a brand new EV due out in 2026.

Tesla’s gigacasting method makes use of big casting machines to make automobile our bodies with just some huge solid elements, saving prices and enhancing effectivity. The corporate started utilizing it to provide Mannequin Y in 2021. Quickly after, a number of Chinese language corporations positioned orders for gigapresses with the LK Group. Hyundai and Volkswagen are additionally mentioned to be investigating the know-how.

Did the latest information that Tesla is outselling Toyota in California apply some warmth to the Japanese automaker’s company posterior? The closest factor to such an admission we’re more likely to hear is that this coy assertion from Chief Manufacturing Officer Kazuaki Shingo: “We’re studying new choices from specialised EV makers to tackle the problem” of electrification.

Supply: CarBuzz, Nikkei Asia

Photographs courtesy of Toyota

[ad_2]