[ad_1]

a brand new proprietary lubrication mechanism considerably reduces the required lubricant provide, contributing to longer eVTOL flight vary

NSK Ltd. has launched a brand new gasoline turbine generator bearing for eVTOLs1 together with massive drones, which is predicted to increase drone flight vary.

The brand new product was used for the gasoline turbine generator of a giant drone (excessive payload emergency provide supply drone geared up with a gasoline turbine generator) geared up with an 80-kw hybrid drive system for a regional reconstruction and sensible improvement promotion venture in fiscal 2023, and delivered to Fukushima Prefecture on February 21, 2024.

NSK goals to attain annual gross sales of 1.0 billion yen by 2030 for this product.

1 eVTOL: electrical vertical take-off and touchdown plane

1. Background

Lately, improvement of eVTOLs has been transferring ahead as a brand new technique of transportation, with a predicted market dimension of 20 trillion yen by 2035. Beforehand, mainstream eVTOL propulsion techniques had been utterly motorized, however to satisfy the rising want for longer flight vary and improved transportation capabilities, demand for high-output, compact, light-weight hybrid motors is predicted to proceed rising. Fuel turbine mills stand out from different hybrid motorized fashions as a result of they’ll use varied gasoline sources akin to biofuels and hydrogen, making them enticing from a carbon neutrality perspective. Now, gasoline turbine mills are the strongest contender for sensible propulsion mechanisms.

To contribute to longer flight vary, decreasing weight (i.e., making oil provide scavenge pumps and the lubricant tank lighter), and delivering high-speed revolution efficiency is required of gasoline turbine generator bearings. To satisfy this want, the market problem is guaranteeing high-speed revolution efficiency (over 2.5 million dmn) with minimal lubrication.

2. Options

NSK has developed a brand new lubrication mechanism that reduces the quantity of lubricating oil the bearing requires whereas additionally reducing energy loss. This design ensures high-speed revolution efficiency (over 2.5 million dmn) with the optimum, minimal quantity of lubricating oil.

1) Decreasing the quantity of lubricating oil

The brand new product reduces the quantity of lubricating oil to 1 quarter of the standard jet lubrication mechanism.

⇒Light-weight oil provide scavenge pumps and lubricant tank

2) Decreasing power loss (energy loss)

The brand new product reduces the facility loss to 2 thirds of the standard jet lubrication mechanism.

3) Making certain high-speed revolution efficiency (over 2.5 million dmn)

3. Know-how

1) Overview of the brand new lubrication mechanism

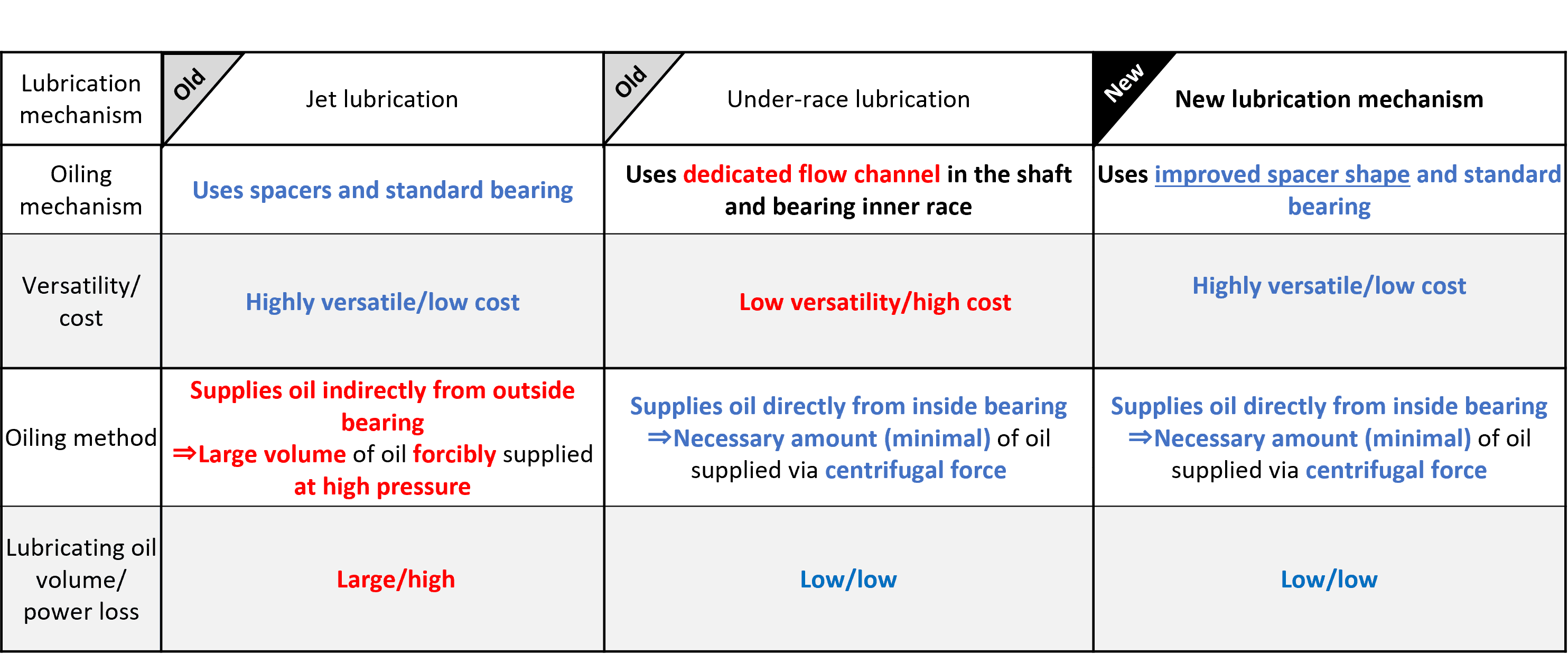

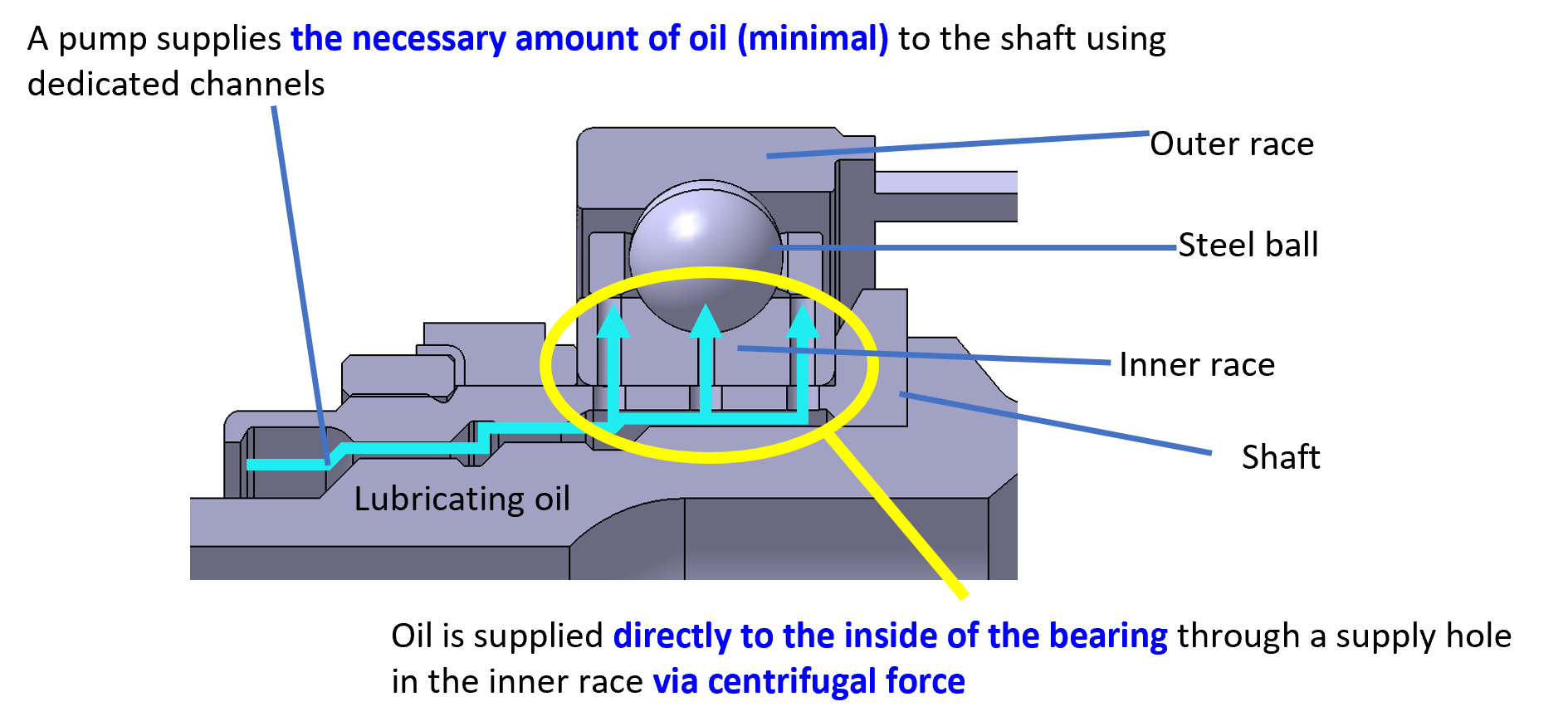

The issue with jet lubrication, a standard lubrication mechanism used for high-speed bearings, is that it requires a considerable amount of lubricating oil and causes excessive energy loss. NSK’s new product resolves this situation by incorporating under-race lubrication as utilized in increased revolution functions, delivering diminished energy loss and lubricating oil quantity.

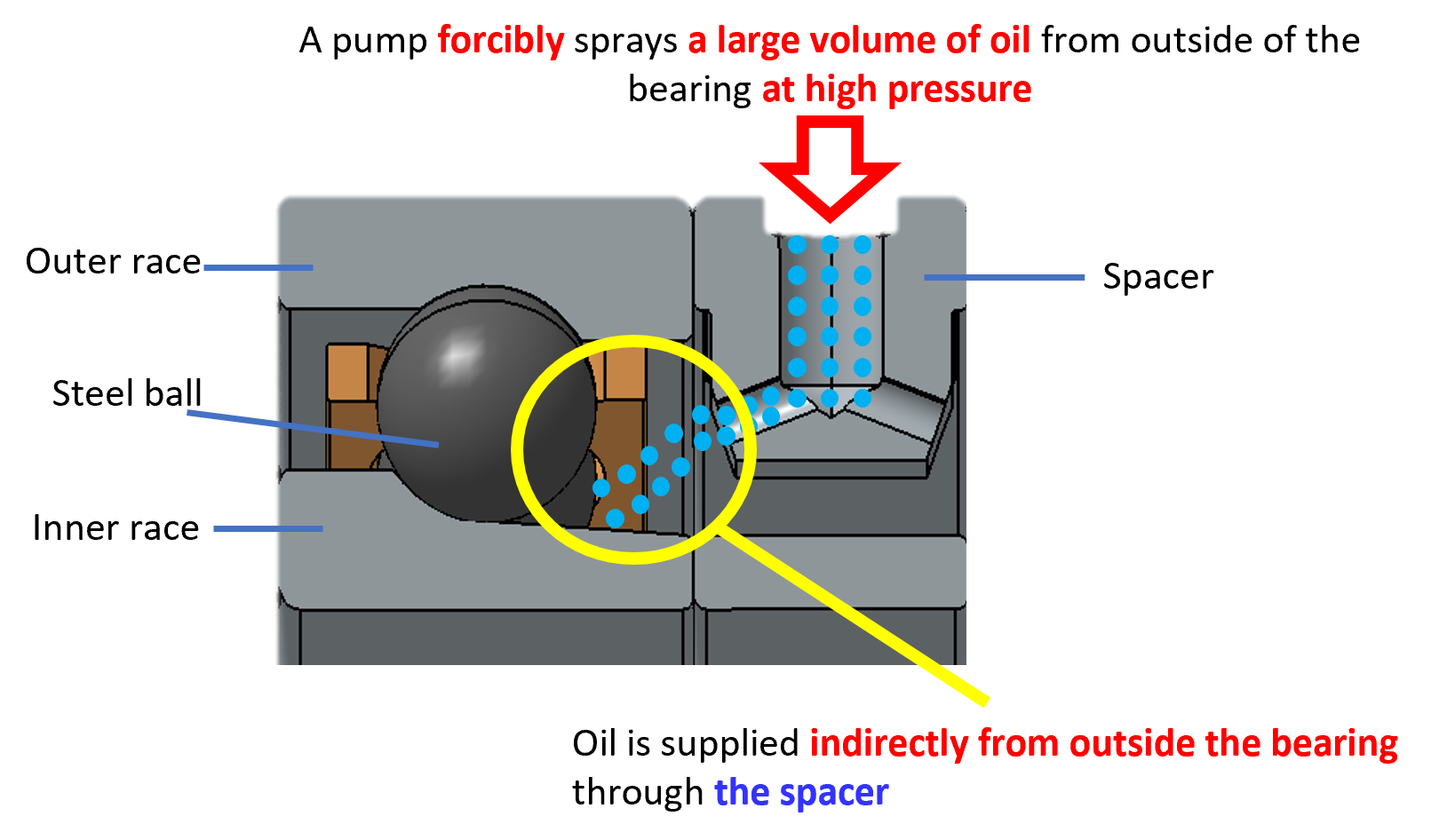

2) Points with the standard lubrication mechanism

Jet lubrication makes use of extremely appropriate elements, spacers, within the oiling mechanism, making it versatile and cost-effective, however a big quantity of oil is forcibly provided at excessive strain from outdoors the bearing, leading to massive quantity lubricating oil utilization and vital energy loss.

Then again, under-race lubrication makes use of devoted move channels within the shaft and bearing internal race to immediately provide oil, a technique which has low versatility and excessive price. The profit is that, since solely the required quantity of oil (minimal) is provided through centrifugal pressure, this technique is gives minimal energy loss and oil utilization.

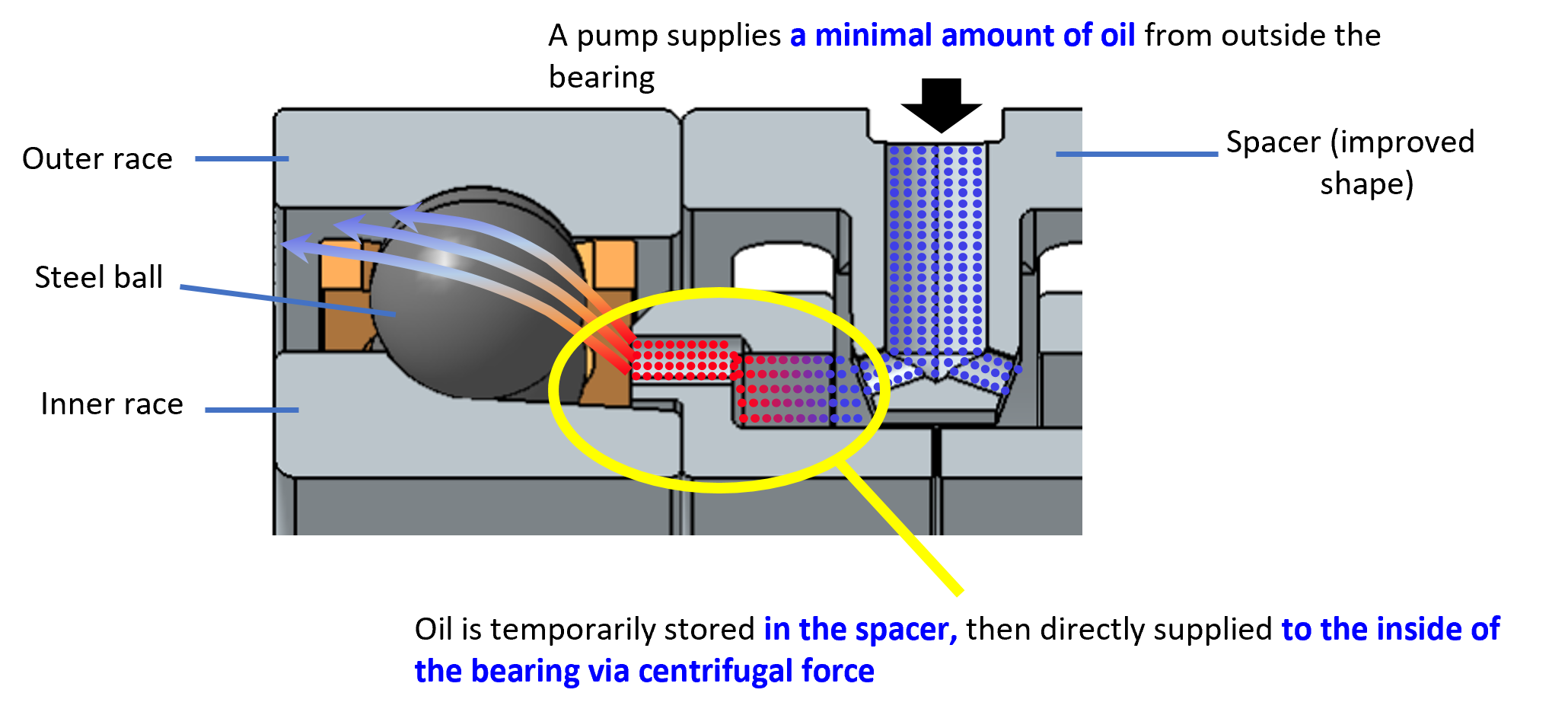

3) New lubrication mechanism

NSK’ new lubrication mechanism options an improved spacer form permitting for direct provide of the required quantity of oil (minimal) to the within of the bearing utilizing centrifugal pressure. This resolution reduces the quantity of lubricating oil and energy loss, yielding a brand new extremely versatile, low-cost lubrication mechanism.

SOURCE: NSK

[ad_2]