[ad_1]

Panasonic Trade Co., Ltd. (Headquarters: Minato-ku, Tokyo; Consultant Director, President, CEO: Shinji Sakamoto) introduced at present that it has begun business manufacturing of its ZL sequence conductive polymer hybrid aluminum electrolytic capacitors. The sequence contains the {industry}’s first high-capacitance kind fashions assured to function at 135°C. These capacitors have been developed for set up in digital management items (ECUs)[1] for electrical automobiles (now typically known as xEVs, a catchall for EVs and all their subtypes), together with hybrids. Mass manufacturing is slated to start in February 2024.

Conductive polymer hybrid aluminum electrolytic capacitors, characterised by excessive capacitance and excessive present, are liable for lowering present noise and stabilizing circuit voltage in ECU energy provide circuits, with greater than 100 packs utilized in a typical xEV. They’re key units which can be indispensable for the electrification and superior digitization of automobiles. Lately, ECUs mounted on automobiles have proliferated, and their energy consumption has elevated in keeping with automobile electrification and the rise of autonomous driving. Specifically, purposes resembling superior driver help programs (ADAS)[2], electrical energy steering (EPS)[3], and automated braking require a redundant design with two an identical circuits put in in a automobile to enhance security, leading to a development in direction of an extra enhance within the variety of capacitors used per ECU. Nevertheless, the restricted house obtainable for set up within the automobile physique requires ECUs to course of excessive currents in a compact dimension, which will increase the quantity of warmth generated inside the ECU. Subsequently, capacitors are required to not solely be extra heat-resistant but in addition smaller in type issue whereas providing extra capacitance than ever earlier than.

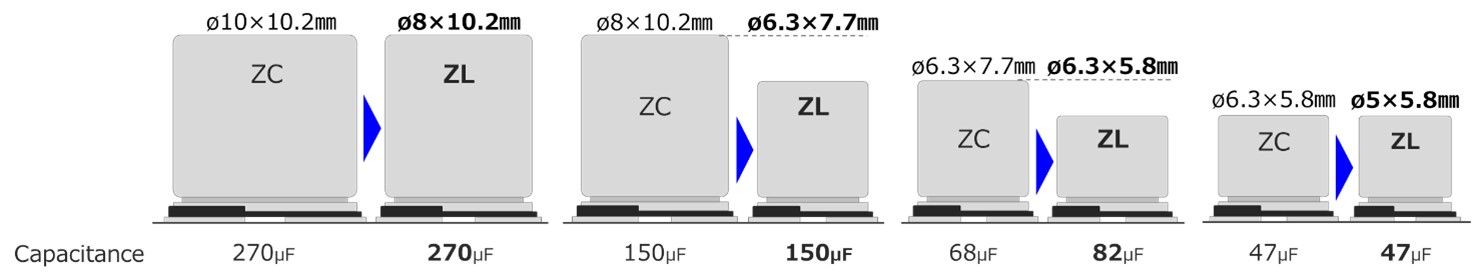

Panasonic Trade started mass producing conductive polymer hybrid aluminum electrolytic capacitors in 2012, and has led the way in which with industry-first merchandise. Not too long ago, the corporate has additional advanced its proprietary electrolyte and high-precision electrode foil winding expertise with a view to business manufacturing of the ZL sequence capacitors. With a lineup of 5 main sizes, these capacitors overcome circuit design restrictions via warmth management measures and obtain a one rank smaller dimension than the corporate’s current customary ZC sequence merchandise with out altering the capacitance.

Using its proprietary system expertise, Panasonic Trade will try to contribute to enhancing the efficiency and reliability of electrical automobiles and cut back tools weight. This, in flip, will result in improved gasoline effectivity and contribute to decreased environmental influence by lowering the amount of components and supplies used.

Panasonic’s automotive conductive polymer hybrid aluminum electrolytic capacitors have the next options:

[ad_2]